Because NO single stakeholder controls the whole chain.

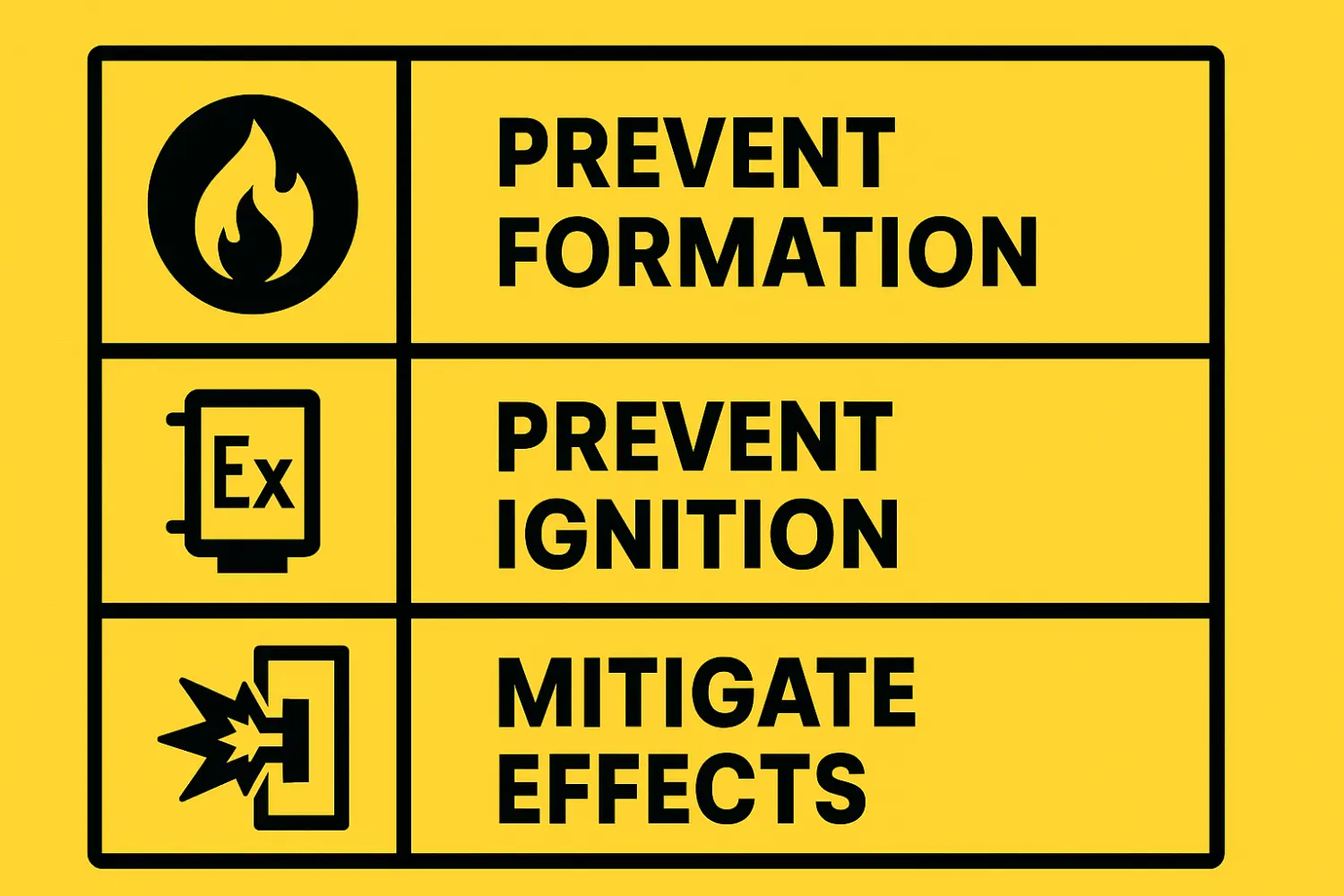

Explosion protection only works when process control (primary), equipment design/selection (secondary), and consequence mitigation (tertiary) all align.

A risk gap occurs if even one stakeholder ignores one layer.

Stakeholder-by-Stakeholder Breakdown

Management / Site Owner

Must know all 3 because they:

❗If management doesn't understand all 3 → wrong investments → noncompliance → liability.

Engineering (Process, Mechanical, Electrical, Instrumentation)

They design and implement:

❗If engineers overlook one layer → design becomes unsafe and not compliant with IEC 60079-14 / 10-1 / 10-2.

Procurement / Purchasing

Often the forgotten but critical group.

They must understand:

❗Purchasing errors → the most common root cause of wrong category, non-Ex equipment, or unsafe substitutions.

Operations / Maintenance

They influence all 3 daily:

❗Incorrect maintenance can destroy any layer instantly.

Inspection / Ex Authorized Persons / Competent Persons

Their role requires understanding all 3 because:

❗If inspectors understand only the "Ex equipment" part → 50% of risks remain undetected.

HSE / Risk / Compliance Officers

Must ensure the entire explosion protection concept is coherent:

❗If HSE views explosion protection only as "equipment category compliance," they miss prevention and consequence reduction.

CEOs / Insurance / Regulators

Understanding all 3 layers allows:

❗Lack of understanding leads to noncompliance, fines, or denied insurance claims.

Keep up good work!

Note: Your comment will only appear on the site after review. Your email address will not be visible, only your name and comment.