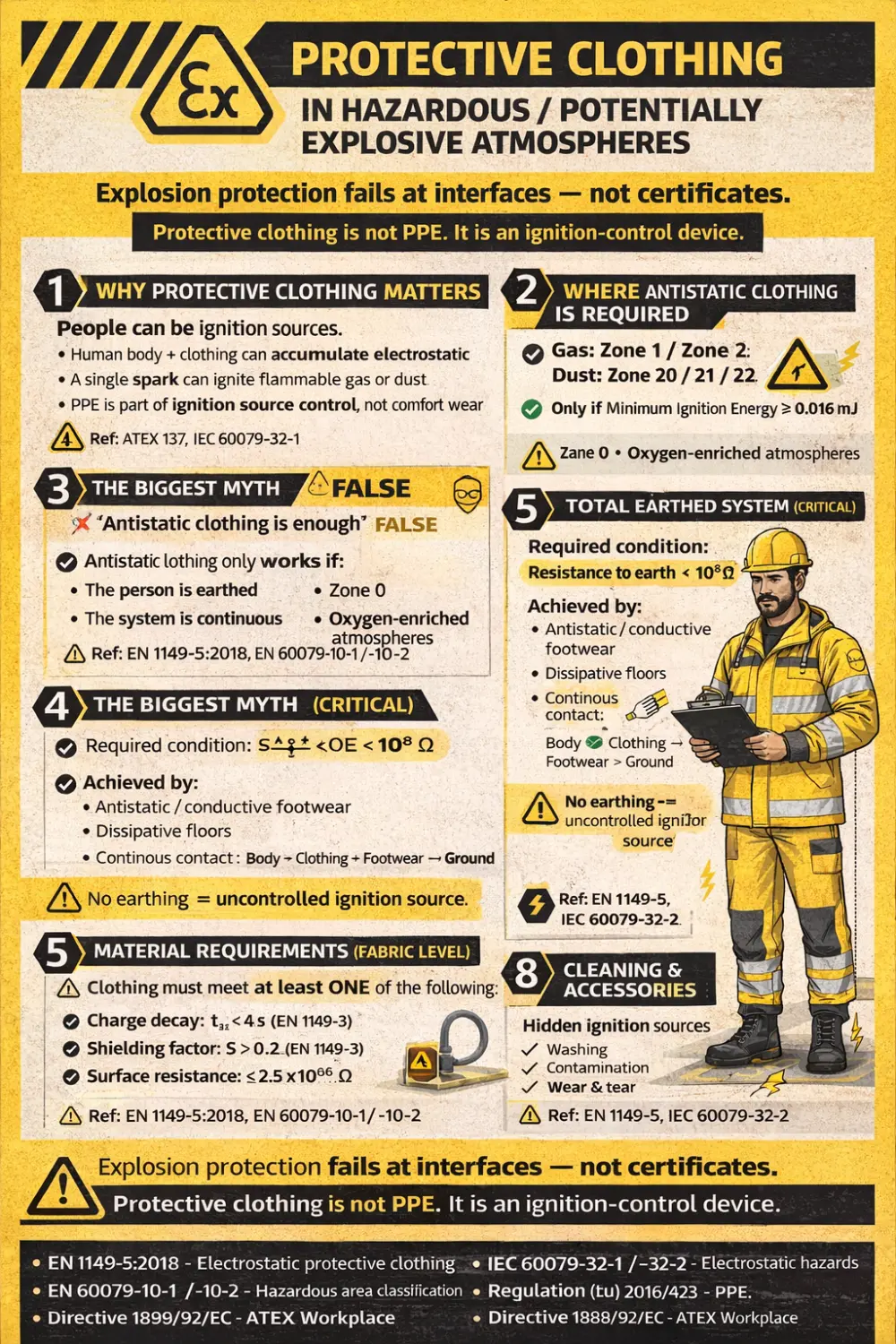

Protective Clothing in Potentially Hazardous Atmospheres (Engineering, ATEX & IECEx perspective – with references)

ATEX Workplace Directive (EU)

Directive 1999/92/EC (ATEX 137) Requires employers to Assess explosion risks, to Prevent ignition sources, including electrostatic discharges from people and clothing; and to Select suitable work equipment and PPE.

Note: Protective clothing is an ignition control measure, not just PPE.

PPE Regulation (Regulation (EU) 2016/425)

PPE intended for potentially explosive atmospheres must be specifically designed and certified. EN 1149-5 provides presumption of conformity for electrostatic risks (Annex ZA).

So the risk actually is Electrostatic ignition risk. Human body + clothing can Accumulate charge by walking, friction, induction and Discharge via spark or brush discharge. The Typical ignition energies here are in case of Many gases/vapours: < 0.2 mJ and Hydrogen: ~0.016 mJ. Clothing can become the primary ignition source if not controlled.

Key references: IEC 60079-32-1 (Guidance); IEC 60079-32-2 (Test methods); EN 1149 series (clothing-specific)

Scope & Applicability of Antistatic Clothing, Where EN 1149-5 applies to potential hazardous area Zones: Gas: Zone 1, Zone 2; Dust: Zone 20, 21, 22. Only where Minimum Ignition Energy ≥ 0.016 mJ and Clothing must be part of a total earthed system. Explicit exclusions are Zone 0 (unless specially justified); Oxygen-enriched atmospheres; Protection against mains voltage and Gloves and footwear (covered by other standards).

Earthing Concept (CRITICAL and often ignored)

Total earthed system requirement where EN 1149-5 requires Resistance from person to earth < 10⁸ Ω. Achieved by: Antistatic / conductive footwear; Dissipative floors and Body → clothing → footwear → ground continuity

Note: Antistatic clothing alone is useless without earthing. References: EN 1149-5, Clause 1 & 6; IEC 60079-32-1

Material Requirements (WHAT the fabric must do regarding Clothing material to meet at least one of the following (after cleaning): Charge decay (Half-decay time: t₅₀ < 4 seconds (EN 1149-3, Method 2); Shielding factor (S > 0.2 (EN 1149-3)); Surface resistance (≤ 2.5 × 10⁹ Ω (EN 1149-1))

Note: Meeting all three is not required and not automatically safer (Reference: EN 1149-5, Clause 4.2.1)

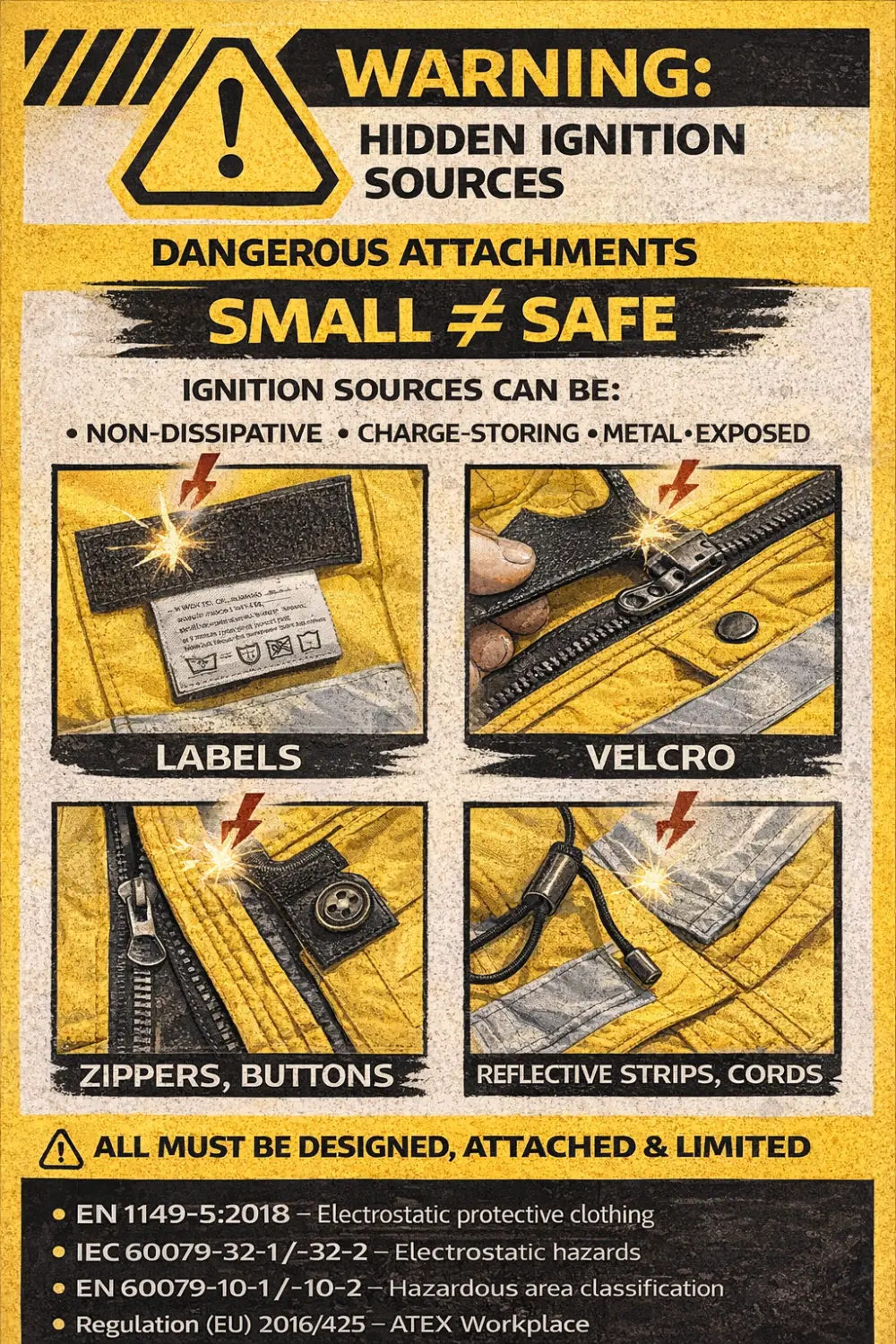

Design & Construction Rules (WHERE most real failures happen)

Clothing must Permanently cover all non-dissipative materials and Remain compliant during movement, bending, work. If multilayer, the Outermost layer must be dissipative and Non-dissipative outer layers are (Max thickness) 2 mm. Conductive threads, If used: Spacing ≤ 10 mm (Reference: EN 1149-5, Clause 4.2.2)

The hidden ignition sources

Labels, reflective strips, Velcro Allowed only if Width ≤ 50 mm; Area ≤ 10,000 mm²; Permanently attached and Total thickness ≤ 2 mm. Zippers, buttons, metal parts Must be Fully covered by dissipative material OR Capacitance < 3 pF. Drawstrings & cords shall be with Max width: 20 mm.

Note: "Small" does not mean "safe" — geometry and capacitance matter (References: EN 1149-5, Clause 4.2.2.2–4.2.2.3; IEC 60079-32-2)

Cleaning, Wear & Degradation (REAL-LIFE issue)

Electrostatic properties Degrade with washing, Degrade with contamination and Degrade with wear. Testing must be done After 5 cleaning cycles, unless otherwise specified. In case of Single-use garments shall be Tested when new

Note: Old antistatic clothing = unknown ignition risk (Reference: EN 1149-5, Clause 4.1)

Marking & User Information (legal defensibility)

Mandatory markings are the Static protection symbol (ISO 7000-2415) and the "Consult instructions" symbol. Mandatory warnings to user, where Manufacturer must state: User must be earthed (<10⁸ Ω); Clothing must not be opened in hazardous areas; Not for oxygen-enriched atmospheres; Not for Zone 0 without approval and Must fully cover non-compliant materials (Reference: EN 1149-5, Clause 5 & 6)

Engineering Reality Check (Ex compliance mindset)

Key truths: Antistatic ≠ explosion-proof; PPE ≠ primary protection; Clothing is one layer in a system. Most incidents occur due to Wrong footwear; Poor grounding; Modified garments; Open zippers / rolled sleeves and Uncontrolled accessories.

Note: Explosion protection fails at interfaces, not certificates

Key Reference List (for reports)

• EN 1149-5:2018 – Electrostatic dissipative protective clothing

• IEC 60079-32-1 – Electrostatic hazards (guidance)

• IEC 60079-32-2 – Electrostatic testing

• EN 60079-10-1 / -10-2 – Hazardous area classification

• CEN/CLC/TR 16832 – Selection & use of PPE for electrostatic risks

• Regulation (EU) 2016/425 – PPE

• Directive 1999/92/EC – ATEX workplace safety

Note: user shall follow IOM and DoC of protective clothing (both IOM and DoC shall indicate the safe use in possible hazardous environment)

Keep up the good work!

Arpad

Co-writer: Geri Varga