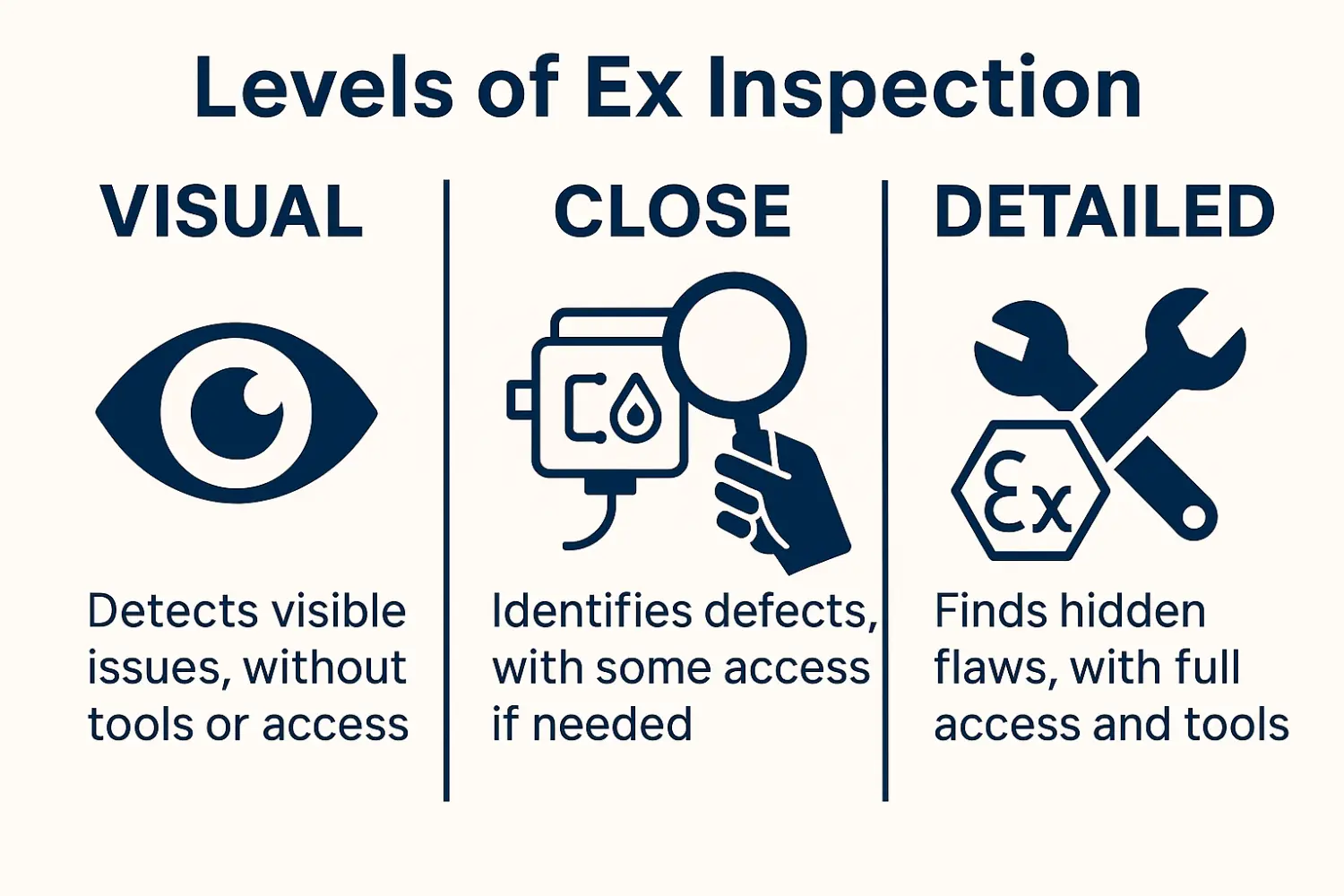

Levels of Ex Inspection

The Ex standards define different inspection grades:

1. Visual inspection

Detects obvious defects (e.g. missing bolts, broken cable gland, damaged enclosure).

No tools required, line-of-sight only.

2. Close inspection

Everything in visual, plus detects defects not obvious unless approached closely (e.g. incorrect gland fitting, missing earth continuity, incorrect marking).

May need access but no dismantling.

3. Detailed inspection

All of visual + close, plus identifies internal defects.

Requires opening of enclosures / dismantling to check terminals, seals, clearances, creepage distances, IP integrity.

In addition, sample-based vs 100% inspection is sometimes allowed, particularly in periodic regimes (IEC 60079-17 Annex C).

What the standards say

IEC 60079-14 (Electrical installations, design, selection, erection)

- Specifies that before initial energization, equipment must be inspected to the appropriate level (usually detailed for new installations).

- This is mainly written for electrical Ex installations.

IEC 60079-17 (Inspection and maintenance)

- Defines inspection grades (visual, close, detailed) and sampling strategies for periodic maintenance inspections.

- Also focused on electrical equipment.

Is this only for electrical, or also for non-electrical Ex equipment?

Historically, these inspection levels were developed for electrical Ex equipment (rotating machines, luminaires, control stations, cable entries).

That's why IEC 60079-14/-17 focus on electrical installation and maintenance.

But the principle has been adopted more widely:

Non-electrical Ex equipment (covered by IEC 80079-36/-37 for construction and marking, ISO/IEC 80079-38 for mining, etc.) still requires inspection — though the standards do not explicitly classify them into visual/close/detailed levels in the same way.

In practice, compliance engineering and operators apply the same regime:

Visual → check marking, mechanical integrity, missing bolts, gaps, damage.

Close → check correct assembly, sealing, gaskets, shaft seals, alignment.

Detailed → dismantle, measure tolerances, check flamepaths, mechanical clearances, gaskets, lubrication, ignition source control.

Thus, while the formal definition comes from the electrical standards, the concept applies equally to non-electrical equipment in Ex areas.

Practical approach (Ex compliance engineering)

Initial verification (before commissioning)

- Always Detailed (100%) for both electrical & non-electrical.

Routine periodic inspections

- Typically Visual (all items) + Close/Detailed (sampled or risk-based).

High-risk items (frequent maintenance, exposed to harsh environments, or safety-critical)

- Require more Close/Detailed inspections.

Non-electrical equipment (pumps, gearboxes, couplings, mechanical drives)

- Apply the same logic, even if the standard is less oriented.

Keep up the good work!

Note: Your comment will only appear on the site after review. Your email address will not be visible, only your name and comment.