Here people are not punished for mistakes caused by poor systems, unclear rules, or complex working conditions. System weaknesses are identified and fixed so errors are less likely to happen again. Accountability remains, but discipline is reserved for deliberate violations, recklessness, or intentional harm.

Just Culture encourages open reporting, transparency, and continuous improvement, which are essential in high-risk industries such as aviation, healthcare, process safety, and Ex (explosion protection) engineering – where learning from small deviations can prevent major accidents.

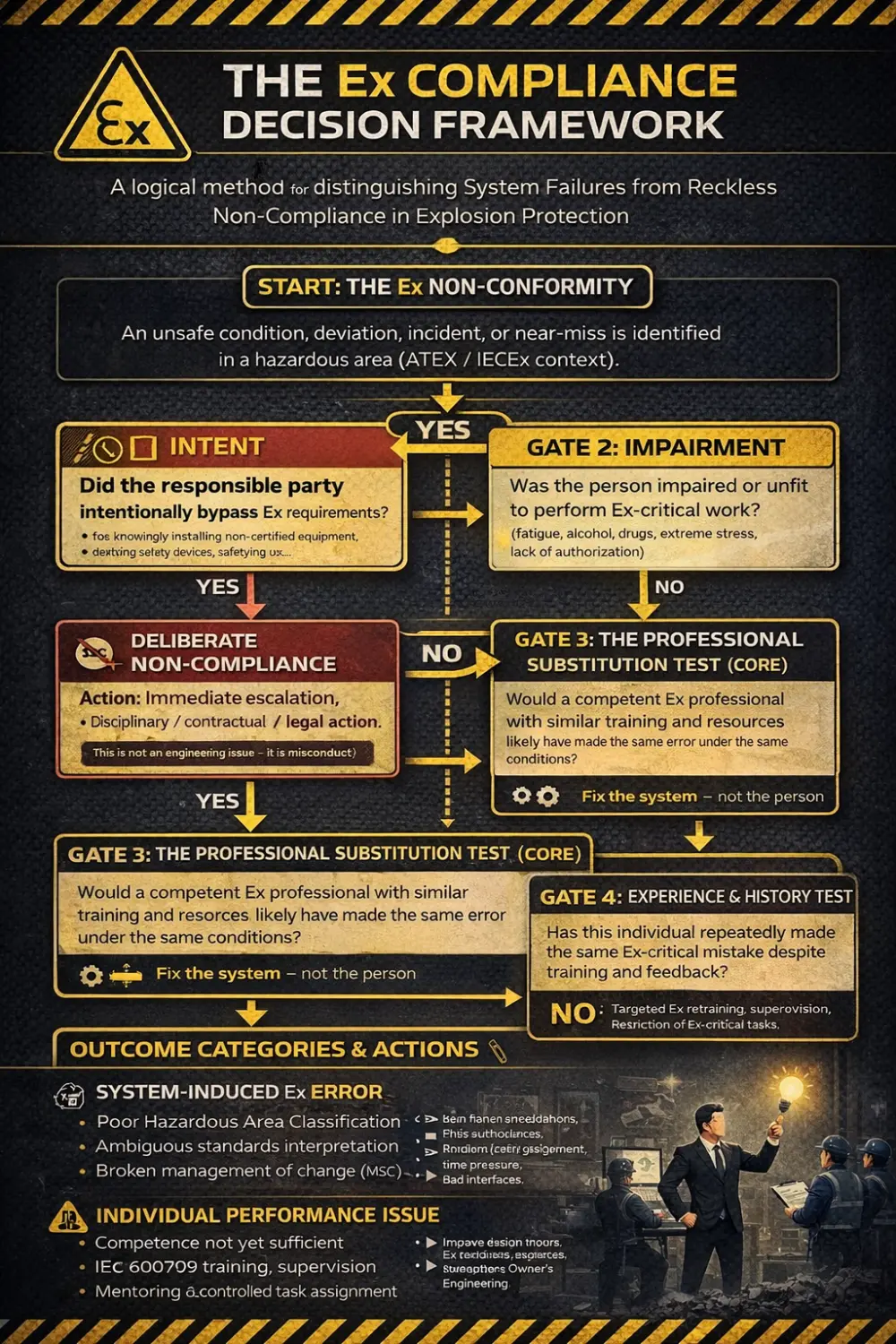

A logical method to distinguish System Failures from Non-Compliance in Explosion Protection

START: THE Ex NON-CONFORMITY

An unsafe condition, deviation, incident, or near-miss is identified in a possible hazardous environment (ATEX / IECEx).

GATE 1: INTENT

Did the responsible party intentionally bypass Ex requirements? (E.g. installing non-certified equipment, defeating safety devices, faking documentation). It is a DELIBERATE NON-COMPLIANCE!

If YES – Action: Immediate escalation, disciplinary / contractual / legal action

(This is not an engineering issue — it is misconduct.)

If NO – Continue to Gate 2

GATE 2: IMPAIRMENT

Was the person impaired or unfit to perform Ex-critical work? (fatigue, alcohol, drugs, extreme stress, lack of authorization)

If YES – IMPAIRMENT-RELATED FAILURE – Action: Remove from task, medical/HR intervention, reinforce fitness-for-duty rules

If NO – Continue to Gate 3

GATE 3: THE PROFESSIONAL SUBSTITUTION TEST (CORE)

Would a competent Ex professional with similar training and resources likely have made the same error under the same conditions?

If YES – SYSTEM-INDUCED Ex ERROR (Unclear standards, poor drawings, missing zoning data, conflicting instructions, time pressure, bad interfaces) – Action: Fix the system — not the person

If NO – Continue to Gate 4

GATE 4: EXPERIENCE & HISTORY TEST

Has this individual repeatedly made the same Ex-critical mistake despite training and feedback?

If YES – INDIVIDUAL COMPETENCE GAP – Action: Targeted Ex retraining, supervision, restriction of Ex-critical tasks

If NO – ISOLATED Ex SLIP / LAPSE – Action: Coach, document lesson learned, improve clarity — then move on

OUTCOME CATEGORIES & ACTIONS

SYSTEM-INDUCED Ex ERROR

Root cause lies in Poor Hazardous Area Classification, Ambiguous standards interpretation, Missing Ex lifecycle ownership, Broken management of change (MoC)

So Action for Fix procedures, data flow, responsibilities, for Improve design inputs, Ex registers, drawings and for Strengthen Owner's Engineering

In case INDIVIDUAL PERFORMANCE ISSUE

Not malicious, but competence not yet sufficient – Action for Ex-specific training (IEC 60079-14 / -17 / -19) and Mentoring and controlled task assignment

ISOLATED Ex SLIP

In case RECKLESS / DELIBERATE NON-COMPLIANCE

THE Ex LEADERSHIP RULE

Over 80–90% of Ex non-conformities are system-induced, not individual failures. If leadership punishes system failures → people stop reporting and fixes systems – safety and compliance improve. Discipline is reserved for the rare cases of deliberate or reckless behavior — not for engineering complexity.

KEY MESSAGE FOR Ex ENGINEERING

Explosion protection is not a checklist problem. It is a system-engineering and lifecycle-ownership problem.

Keep up the good work!

Note: Your comment will only appear on the site after review. Your email address will not be visible, only your name and comment.