Valid terms related to Ex compliance engineering. Trendy words, each and every person is familiar within process safety related industries.

Besides all specially important to the exceptions of explosion protection such as gun powder, ammonium nitrate, trucks and lorries, households and many more where accidental ignition may cause unwanted incident but legally not directly related.

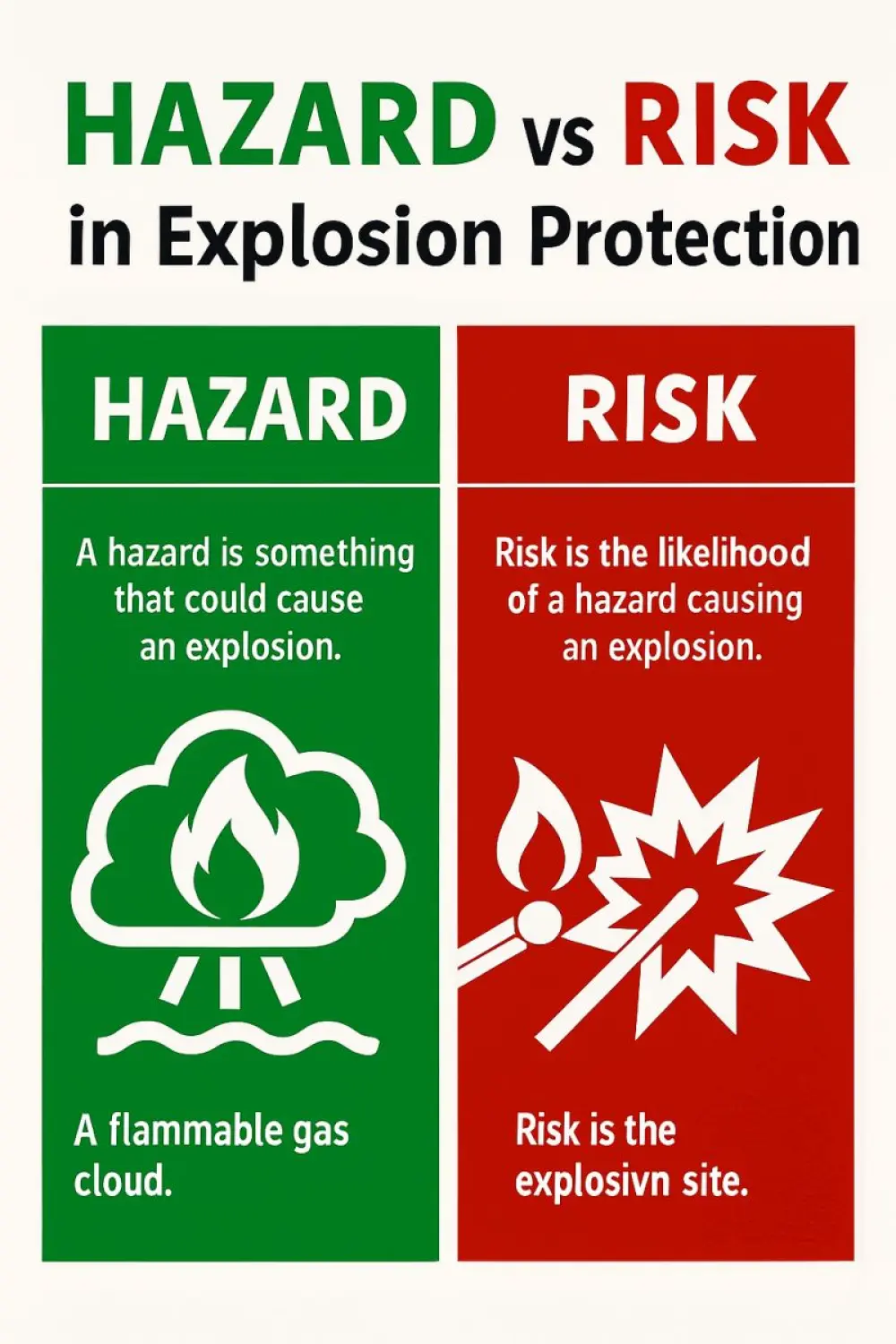

Hazard in Ex protection

Definition: A hazard is something that has the potential to cause an explosion.

Examples:

o Flammable gases, vapors, dusts (e.g., methane, propane, flour dust).

o Ignition sources (sparks, hot surfaces, static electricity).

o Confined spaces where explosive atmospheres may accumulate.

Hazards are always present in hazardous areas; they cannot be fully eliminated (e.g., a chemical plant will always have solvents, or a silo will always have combustible dust).

Risk in Ex protection

Definition: Risk is the likelihood and severity of an explosion occurring due to the hazard.

Examples:

o Probability that a flammable gas cloud ignites because of faulty equipment.

o Consequences of an ignition inside a dust collector.

o Likelihood of static discharge igniting vapors during tank filling.

Risk depends on probability × consequence.

How to deal with hazards and risks in Ex

Hazard identification (HAZID, HAC):

o Identify all explosive atmospheres (gases, vapors, dusts).

o Classify zones (Zone 0/1/2, 20/21/22) according to IEC 60079-10.

Risk assessment (HAZOP, SIL, ignition analysis):

o Evaluate likelihood of ignition.

o Estimate consequences of explosion (blast, fire, toxic release).

Risk reduction measures:

o Eliminate or reduce hazards if possible (use inerting, ventilation, substitution).

o Control ignition sources:

- Ex-certified equipment (per IEC 60079-14, ATEX, IECEx).

- Intrinsically safe circuits (Ex i), flameproof enclosures (Ex d), pressurization (Ex p), etc.

o Administrative measures:

- Permit-to-work, training, competency management.

o Protective systems:

- Explosion venting, suppression, isolation.

Residual risk management:

o Define what risks remain after protective measures.

o Ensure they are as low as reasonably practicable (ALARP).

In short:

• Hazard = explosive atmosphere itself (gas, dust, vapor).

• Risk = probability + consequence of explosion actually occurring.

• Dealing with them = Hazardous Area Classification + proper Ex design + continuous risk assessment.

Keep up good work!

Arpad

veress@exprofessional.com

Note: Your comment will only appear on the site after review. Your email address will not be visible, only your name and comment.