The Regulation (EU) 2024/573 of the European Parliament and of the Council, adopted on 7 February 2024, introduces a new framework for controlling fluorinated greenhouse gases (F-gases).

It repeals Regulation (EU) No 517/2014 and amends Directive (EU) 2019/1937, with the main goal of accelerating the reduction of F-gas emissions in line with the EU's climate-neutrality objectives by 2050.

Mandatory Leakage Detection Systems

A key requirement is the installation and regular verification of leakage detection systems in all applications using fluorinated gases or hydrocarbon refrigerants above certain charge thresholds.

Operators and owners of such systems are obliged to:

These obligations apply to:

From Climate Regulation to Explosion Protection

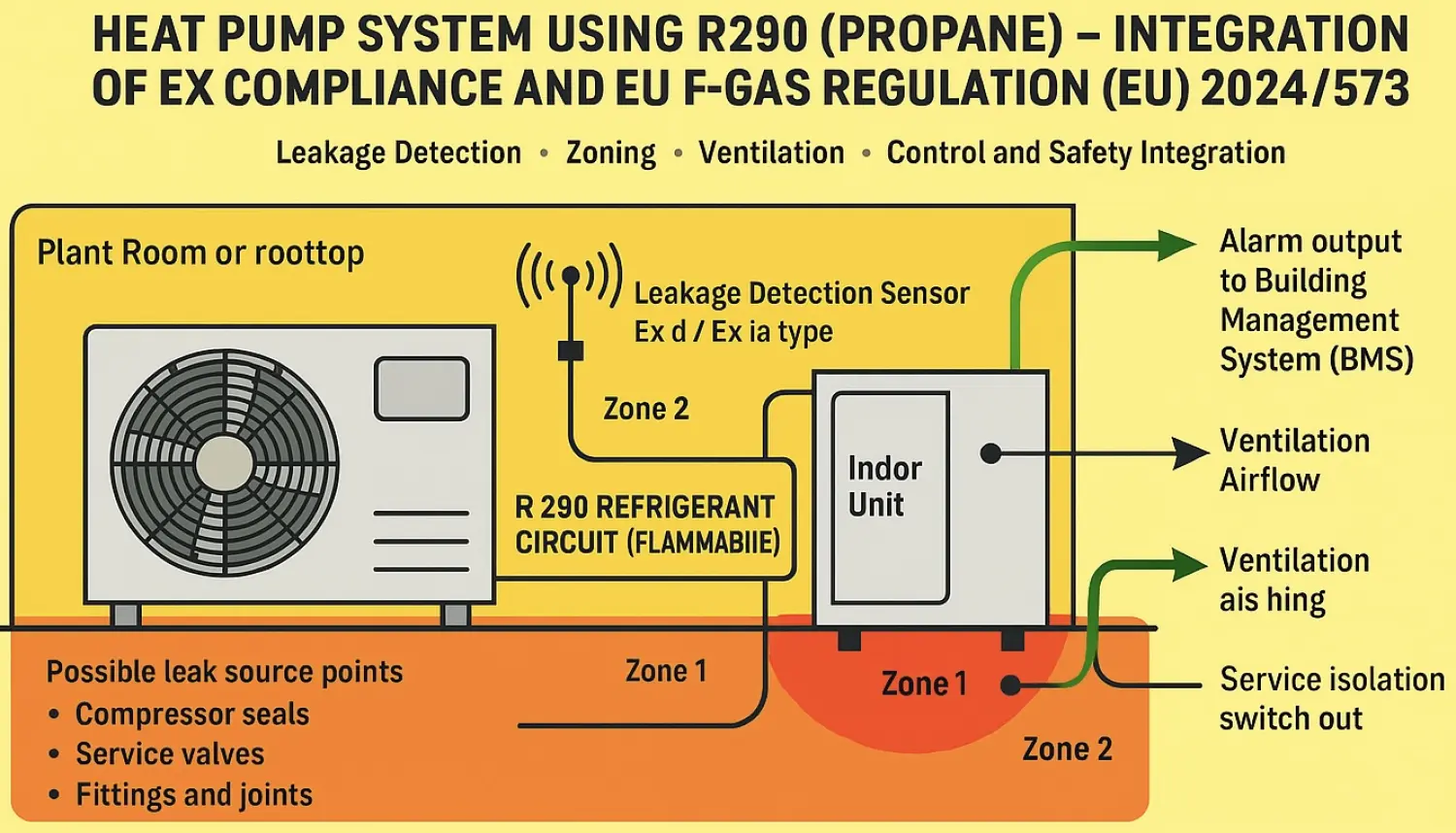

While this regulation primarily addresses environmental sustainability, it also directly impacts the field of explosion protection (Ex) — especially where hydrocarbon-based refrigerants such as R290 (propane) or R600a (isobutane) are used as low-GWP alternatives.

These substances are flammable, which means all equipment, components, and servicing activities must comply with the ATEX Directive 2014/34/EU and the IEC 60079 series of standards.

Separation of Ex Compliance Engineering: Household vs Industrial Facilities

The application of Ex compliance engineering depends strongly on the installation environment and intended use of the equipment.

Household and Small Commercial Installations

Industrial and Commercial Facilities

This separation ensures proportional safety measures:

while household users rely on product conformity and good installation practice, industrial operators must maintain a comprehensive Ex compliance management system covering design, inspection, and record-keeping.

New Challenges — and Opportunities — for the Industry

Regulation (EU) 2024/573 sets new expectations for all stakeholders:

Conclusion

The transition toward low-GWP refrigerants like propane represents both a sustainability milestone and a renewed safety challenge.

To succeed, companies must bridge the gap between environmental compliance and explosion protection discipline — ensuring that the "green" solution remains also safe and Ex-compliant.

The listed values are from the hungarian version of the same.

At ExProfessional.com we continuously track legislative developments and provide guidance to help operators, designers, and inspectors implement integrated compliance strategies — where climate responsibility and explosion safety meet.

Keep up the good work!

Arpad

veress@exprofessional.com

Note: Your comment will only appear on the site after review. Your email address will not be visible, only your name and comment.