Why Flow Matters in Ex Compliance

Explosion protection is not a field where shortcuts or half-focus are acceptable.

Ex professionals — whether designing, installing, inspecting, or maintaining equipment — carry a responsibility where noncompliance can have catastrophic consequences.

The flow attitude is essential, because it ensures complete immersion in the task (no distraction in critical assessment, design or inspection steps). It aligns high skill with high challenge, the central axis of Csikszentmihalyi's model. It transforms Ex compliance from a burden into a professional craft that generates meaning and pride.

Main Factors here

Competency and Mastery (Skills Dimension)

Flow emerges when skill level matches the challenge. In Ex compliance, this is achieved through high-level Ex personnel competency: certified training, continuous learning, and practical experience. Example: An Ex inspector identifying subtle non-conformities in a hazardous area installation without overthinking — the skill is hardwired.

Clear Goals and Standards (Goal Dimension)

Flow requires clear objectives. Ex compliance provides these through standards, directives, and codes (ATEX, IECEx, IEC 60079, ISO 80079, API RP 505). When engineers know exactly what "good" looks like, their work aligns with compliance.

Immediate Feedback (Feedback Dimension)

Flow thrives when actions have instant feedback. In Ex engineering, this comes from inspection findings, test results, or risk assessment outcomes. Digital tools (e.g., Ex registers, AI assistants) can further enhance feedback loops, allowing engineers to self-correct and refine continuously.

Balance of CAPEx and OPEx

Flow is disturbed when long-term goals conflict with daily tasks. In Ex compliance, both CAPEx (investment in certified equipment, proper design) and OPEx (maintenance, periodic inspections, competence management) must be balanced. A well-maintained system avoids breakdowns, creating confidence and stability — conditions for flow.

Motivation

Flow is fueled by the love of the process itself. Ex compliance professionals who see their work as protecting lives, assets, and the environment derive satisfaction. This mindset transforms compliance from "tick-box" duty into meaningful engineering practice.

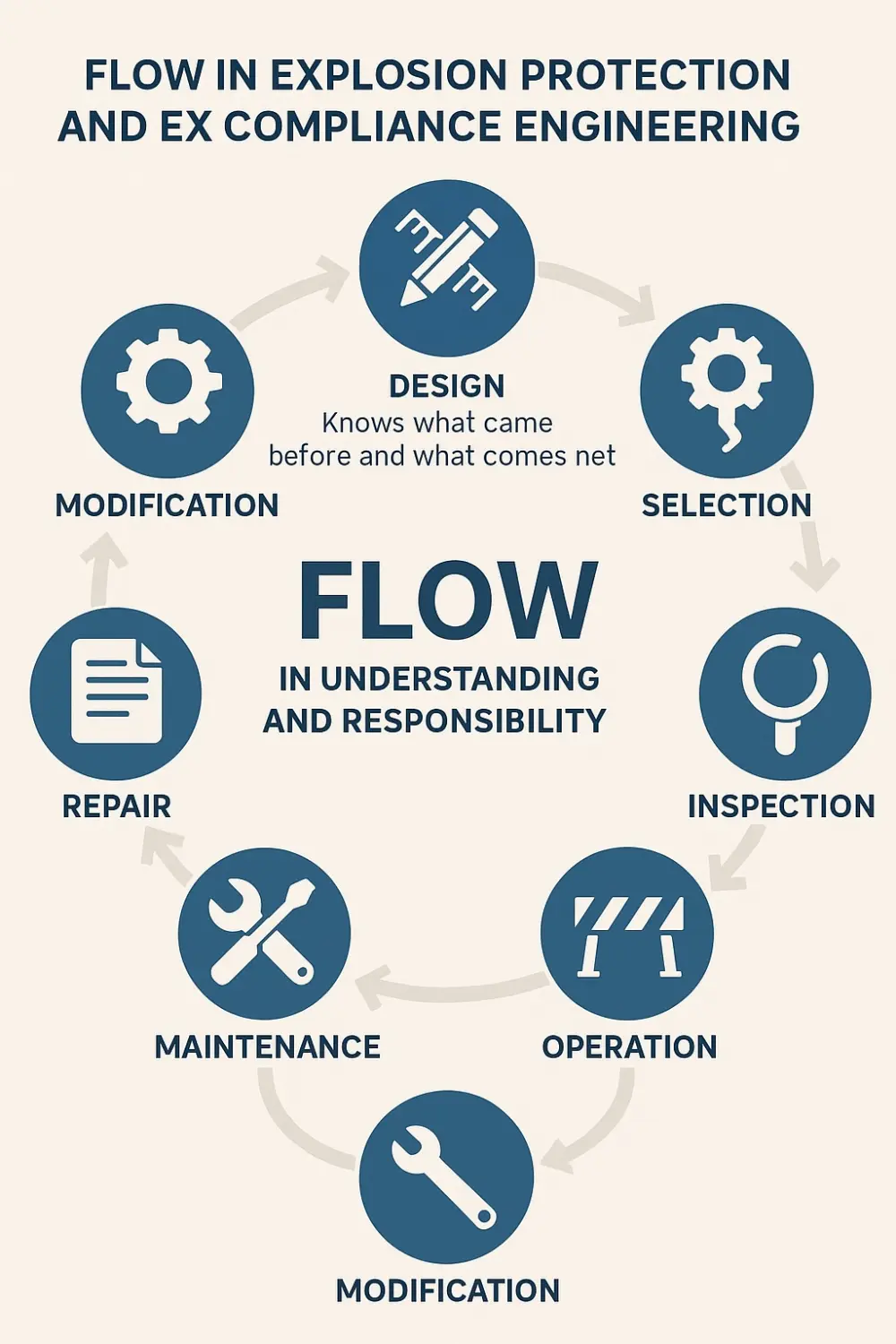

Flow Model Applied to Ex Engineering

Anxiety Zone: Engineer lacks competency but faces high compliance challenges. (Risk of mistakes, unsafe practices)

Boredom Zone: Engineer has skills, but compliance tasks are reduced to bureaucracy without challenge. (Loss of motivation, box-ticking mentality)

Flow Zone: Engineer's competency and challenges are matched—designing, reviewing, or inspecting with deep focus, pride, and accuracy.

The goal for organizations is to ensure their Ex personnel are systematically placed in the Flow Zone through training, empowerment, and resources.

Conclusion: Flow as a Professional Attitude

Ex compliance engineering requires more than technical knowledge. It demands an attitude of flow — where skills, standards, goals, and intrinsic motivation converge.

When Ex professionals work in this mindset, compliance is not just ensured — it is elevated. The result: safer plants, optimized costs (CAPEx & OPEx) and resilient organizations.

Explosion protection, ultimately, is not only about equipment and zones — it is about people in flow, doing their best work where it matters most.

further info: Miklos Csikszentmihalyi

Keep up good work!

Note: Your comment will only appear on the site after review. Your email address will not be visible, only your name and comment.